Understanding Production Planning in the Textile Industry

“Failing to plan is planning to fail.”

It’s a saying we’ve all heard – but nowhere does it hit harder than in textile and apparel manufacturing.

In an industry where one delayed process can derail an entire delivery, planning isn’t just a managerial task. It’s the invisible backbone that keeps the supply chain synchronized, machines utilized, workers coordinated, and customers satisfied.

Whether it’s weaving or dyeing, cutting or finishing, every department relies on accurate timing, material readiness, and capacity visibility.

Yet many manufacturers still depend on spreadsheets or disconnected tools – approaches that simply cannot handle the complexity of modern textile production.

To understand why planning is so crucial, and what makes it uniquely challenging in the textile industry, let’s break down the real dynamics behind production planning module within industry-specific ERP System for Textile and Apparel.

Why Production Planning Is So Challenging in the Textile & Apparel Industry

Textile manufacturing is one of the most diverse and interdependent supply chains in the world. Unlike linear production environments, textiles operate through clusters of processes, each with its own timing, dependencies, and constraints. Some core factors that complicate planning include:

• A highly fragmented process structure

Spinning → weaving → dyeing → finishing → cutting → sewing → packing. Each stage depends on the previous one being completed exactly on time.

• Demand variability and seasonality

Fashion seasons, new collections, and unpredictable trends create constant fluctuations in order volume and mix.

• Mixed production models

Many companies simultaneously operate:

Make to Order (MTO)

Make to Stock (MTS)

Hybrid or “finish-to-order” scenarios

Balancing all three requires more than intuition.

• Material and capacity constraints

Late yarn deliveries, limited loom availability, dye-house bottlenecks, or reliance on subcontractors all impact the plan.

• Increasing product variety

More SKUs → smaller batches → more setups → more complexity.

• The domino effect of delays

One postponed dye bath or finishing batch can cascade through the entire workflow, impacting dozens of customer orders. This delicate ecosystem makes planning not just helpful – but absolutely essential.

The Core Purpose of Production Planning in Textiles

Production planning answers one central question: “How do we align what customers want with what our factory can deliver?” To achieve this, planning must:

• Balance demand with production capacity

• Ensure materials, machines, and labor are available at the right time

• Set realistic delivery commitments

• Sequence activities to avoid bottlenecks

• Coordinate purchasing, production, and inventory teams

• Minimize overtime, idle periods, and unnecessary costs

When planning is effective, production flows smoothly. When it fails, chaos becomes the default.

Common Planning Methods Used in the Textile Sector

Different business models require different approaches to planning.

• Make to Order (MTO)

Production triggered only when customer orders are received. Ideal for custom fabrics, fashion items, or high-variety product lines.

• Make to Stock (MTS)

Products manufactured in advance based on forecast or historical demand. Common in staple items or fast-moving basics.

• Hybrid Models

Some materials or semi-finished goods kept in stock, while final finishing is completed per customer order – especially useful in apparel and home textiles.

• Forecast-based material purchasing

Raw materials (such as yarn or dyes) are often purchased based on projected needs, even if final orders are not yet in place. The ability to support multiple planning methodologies is crucial, because most textile factories use more than one simultaneously.

The Role of Forecasting in Textile Production Planning

Planning starts long before production, it begins with predicting demand. In textiles, forecasting must consider:

Seasonality (spring/summer, fall/winter collections)

Market trends (colors, patterns, textures)

Customer behavior

Sales history at family, style, or product level

Emerging opportunities in new markets

Good forecasting reduces last-minute changes, prevents material shortages, and improves production stability. Poor forecasting does the opposite:

→ overstocks,

→ stockouts,

→ emergency production,

→ and wasted resources.

Planning vs. Scheduling: Understanding the Difference

These two concepts are often confused, but they serve different purposes.

Production Planning

Focuses on what needs to be produced, how much, and when. It is demand-oriented, long- to mid-term, and resource-aware.

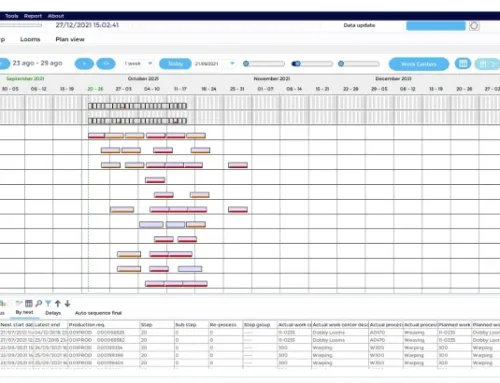

Production Scheduling

Focuses on how production is executed on the shop floor (as explored in our article on Understanding Machine Job Scheduling (MQM):

Which machine?

Which operator?

In what sequence?

How to minimize setups and delays?

Think of it this way:

Planning sets the direction.

Scheduling handles the execution.

When the two are disconnected, operations suffer: missed deadlines, bottlenecks, excessive WIP, or underutilized machines.

What Good Production Planning Enables in Textile Operations

Effective planning creates a ripple effect of improvements across the factory:

• Reliable delivery commitments

Customer service teams can promise realistic ship dates.

• Reduced production fire-fighting

Less chaos → fewer urgent changes → smoother operations.

• Lower work-in-process (WIP)

Material flows steadily rather than piling up between stages.

• Better machine and labor utilization

No idle periods from missing materials or overbooked work centers.

• Improved coordination across departments

Sales, procurement, dye-house, weaving – all aligned under the same plan.

• More predictable costs

A stable production environment lowers overtime, rush orders, and waste. Planning becomes the anchor that stabilizes the entire organization.

Challenges Factories Face When Using Manual or Outdated Planning Methods

Many manufacturers still rely on Excel, whiteboards, or home-grown tools. But these methods collapse when complexity increases. Common issues include:

• Inability to manage multi-level demand (lots, batches, colorways)

• No real-time capacity visibility

• Plans that fall apart as soon as something changes

• Misalignment between purchasing and production timing

• Difficulties tracking WIP or machine availability

• Over-dependence on one experienced planner

• No simulation or scenario planning capability

Manual planning is slow, error-prone, and reactive. Modern textile operations require responsiveness that paper and spreadsheets cannot provide.

How Integrated Planning Supports Operational Reliability

When planning is tied into real-time data – sales orders, inventory, purchasing, machine capacity – decision-making becomes significantly more accurate. Integrated planning enables:

• Early visibility of shortages or overloads

• Immediate effects of order changes reflected across departments

• Better alignment between sales commitments and factory capacity

• Material availability checks before scheduling begins

• Cross-department collaboration based on shared information

This coordination becomes even more effective when planning is closely linked with the production processes managed within NOW ERP. Most importantly: Integrated planning ensures that planned results are actually achievable. This is the foundation of operational reliability.

From Planning Challenges to Industry 4.0 Transformation

The textile industry is rapidly evolving:

· Faster fashion cycles

· More customization

· Higher sustainability expectations

· Rising global competition

Planning is at the center of this transformation. With digital tools, factories can:

· Simulate multiple production scenarios

· Adjust plans instantly when changes occur

· Visualize dependencies across processes

· Anticipate capacity shortages

· Align purchasing and production seamlessly

· Move from reactive to predictive operations

In other words, modern planning is not just about meeting deadlines – it’s about preparing factories for the future of manufacturing.

Conclusion: Better Planning Creates More Predictable Operations

Production planning is where business strategy meets operational reality. In the textile and apparel industry, where complexity is high and margins are tight, planning becomes a strategic advantage.

To explore how textile-focused planning systems support these goals, visit the Planning Module page or book a free consultation with one of our experts.