MQM: Understanding Machine Job Scheduling in Textile Production

In textile and apparel manufacturing, every second counts. From spinning to sewing, hundreds of processes must be perfectly synchronized to meet delivery deadlines, keep costs under control, and satisfy increasingly demanding customers.

Yet, manual scheduling methods often fall short, leading to bottlenecks, missed deadlines, and rising overtime costs.

This is why machine job scheduling software has become essential. By using tools like Machine Queue Management (MQM) — developed as part of Datatex NOW ERP for textile and apparel manufacturers gain the visibility and control needed to optimize machine workloads, minimize idle time, and maximize on-time deliveries.

Why Scheduling Is So Complex in Textile and Garment Manufacturing?

Textile production is one of the most intricate supply chains in the world. Unlike other industries, where production may be linear, textile and garment production involves multiple interdependent steps such as:

• Spinning, dyeing, and weaving of yarn and fabric

• Printing, finishing, and embellishments

• Cutting, sewing, and garment washing

Each stage depends on the availability of both machines and materials. Delays in one department ripple through the entire production chain. Some of the biggest challenges include:

• Shorter lead times as fast fashion and consumer personalization trends grow.

• Higher variety and smaller batches, forcing factories to switch machine setups more often.

• Limited visibility, when planners rely on spreadsheets or disconnected tools.

• Overlapping processes that require constant re-checking of capacity, material readiness, and labor availability.

The result? Frequent rescheduling, unexpected bottlenecks, and difficulties in keeping promises to customers.

What Machine Job Scheduling Brings to the Industry?

Machine job scheduling software addresses these challenges by transforming a traditionally manual and time-consuming task into a visual, data-driven process.

With MQM, planners can:

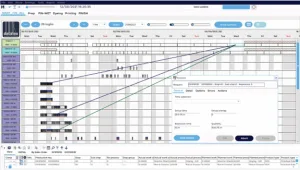

• Use visual Gantt charts to see job assignments in real time.

• Apply automatic sequencing and heuristic algorithms that suggest the most efficient machine-job match.

• Schedule at both single-resource and work-center level, ensuring consistency across departments.

• Run what-if scenarios to compare alternatives before committing to a plan.

This approach makes scheduling faster, clearer, and more effective — even in dynamic production environments where last-minute changes are inevitable.

Key Benefits of Machine Job Scheduling for Textile and Apparel

Companies that implement advanced job scheduling see tangible improvements across the business:

On-time delivery – Optimized sequencing helps meet tight deadlines consistently.

Better resource utilization – Machines, labor, and materials are used more efficiently, with fewer idle periods.

Lower costs – Reduced overtime, shorter lead times, and minimized WIP inventory.

Greater flexibility – Planners can quickly adjust schedules when orders change.

Improved service levels – Reliable deliveries increase customer satisfaction.

Instead of juggling manual rescheduling, planners focus on fine-tuning operations — making scheduling a strategic advantage rather than a bottleneck.

Why ERP Integration Makes the Difference?

Not all scheduling tools deliver the same results. Standalone applications may improve visualization, but they lack the real-time connection to production data that ensures accurate decision-making.

The MQM module in Datatex ERP NOW Modular System is tightly integrated with core ERP functions, which means:

Production orders, work centers, and calendars flow directly into the scheduler.

Material and resource checks ensure that a job isn’t planned without required inputs.

Role-based access enables multiple users (managers, planners, suppliers) to collaborate securely.

Scheduled results feed back into ERP, keeping all departments aligned.

This seamless loop between ERP and scheduling eliminates data silos and ensures that production plans are always current, reliable, and executable.

Advanced Features That Support Efficiency

Beyond core scheduling, MQM offers advanced capabilities tailored to textile and apparel needs:

• Compatibility rules (job-to-resource, job-to-job, capacity reservations) to minimize setup times and prevent incorrect machine allocations.

• Overlap detection and bottleneck alerts to highlight risks early.

• Material availability checks with visual indicators for missing inputs.

• Multi-department and multi-user functionality, making it scalable across large plants.

• Learning curve integration in sewing departments to account for operator skill levels.

These features allow companies to plan not just efficiently but realistically, considering every variable that impacts production performance.

From Bottlenecks to Industry 4.0 Readiness

The textile market is under pressure from global competition, shrinking margins, and rising customer expectations. Companies that continue relying on manual scheduling or outdated tools risk falling behind.

Machine job scheduling software like MQM supports the shift toward Industry 4.0 manufacturing, where real-time data, automation, and digital collaboration drive efficiency. With the ability to quickly re-plan, simulate alternatives, and respond to sudden changes, manufacturers can remain competitive in a fast-moving market.

Conclusion

In a production environment as complex as textiles, effective scheduling is not optional — it’s a necessity. Machine job scheduling with MQM turns scheduling into a strategic advantage by improving on-time deliveries, reducing costs, and optimizing resources.

By combining visual scheduling with ERP integration, MQM ensures that every job is placed on the right machine, at the right time, with the right resources.

Discover how MQM can transform your production by visiting our Machine Job Scheduling (MQM) module page or book a free demo!