Maximizing Fabric Quality with CATS: An Integrated NOW ERP Solution

In the textile and apparel industry, ensuring fabric quality is crucial for brand reputation and customer satisfaction.

Manufacturers must detect and manage defects efficiently to minimize waste, improve profitability, and maintain high-quality standards.

This is where CATS (Computer Aided Textile Supervision) comes in—a powerful fabric inspection and cut optimization software integrated with NOW ERP Apparel Software to streamline production processes.

What is CATS (Computer Aided Textile Supervision)?

CATS is a real-time fabric inspection and optimization system designed for textile and apparel manufacturers.

It provides an advanced solution for identifying fabric defects, mapping them digitally, and optimizing cuts to maximize first-quality output.

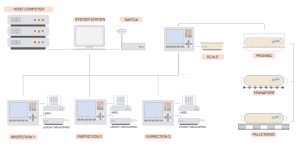

Seamlessly integrated with Datatex NOW ERP System, CATS enhances fabric quality management by offering a complete view of defect data, inventory tracking, and automated decision-making.

Key Features of CATS

Fabric Quality Control with Real-Time Defect Mapping

CATS enables manufacturers to conduct thorough visual fabric inspections, capturing every defect through real-time mapping. Operators can easily classify defects, assign severity levels based on customer requirements, and visualize defect distribution on digital maps.

This data is invaluable for analyzing production trends and implementing preventive quality control measures.

Cut Optimization for Maximum First-Quality Output

The software’s cut optimization module enhances yield by determining the best cutting points on a roll based on defect patterns.

By using advanced algorithms, CATS ensures minimal fabric waste and maximum first-quality production.

Manufacturers can combine second-quality pieces into premium-grade rolls, increasing overall efficiency and profitability.

Seamless ERP Integration for Enhanced Production Insights

As a native module of NOW ERP, CATS seamlessly transfers defect data, roll mapping, and cut optimization details across production, warehouse, and fulfillment operations.

This integration enables manufacturers to track defects back to specific machines, processing lots, or production shifts, allowing for data-driven quality improvements.

Flexible and Configurable for Diverse Manufacturing Needs

CATS adapts to different quality assessment standards, defect classification methods, and customer-specific requirements.

With customizable inspection rules, reporting formats, and label designs, textile manufacturers can configure the system to match their operational needs.

The software also integrates with barcode scanners, scales, and vision-based inspection systems for automated data capture.

The Benefits of Using CATS in Textile Manufacturing

Improved Fabric Quality: Enables proactive defect management and better decision-making.

Higher Production Efficiency: Reduces waste, optimizes fabric usage, and increases first-quality output.

Seamless Data Integration: Links inspection data with ERP systems for real-time inventory and production tracking.

Customizable Quality Standards: Adjusts to diverse quality classifications and customer demands.

Enhanced Profitability: Maximizes the yield of premium fabric while reducing unnecessary costs.

Conclusion

For textile and apparel manufacturers, ensuring high fabric quality while minimizing waste is a competitive necessity.

CATS, integrated with NOW ERP, provides an all-in-one solution for fabric inspection, defect mapping, and cut optimization.

By implementing this software, manufacturers can enhance productivity, reduce fabric defects, and boost overall profitability in a highly competitive market.

Want to learn how CATS can transform your textile manufacturing process? Download CATS brochure or Contact us today to explore its full potential!