Textile Mills: an inside look at the textile manufacturing process

Have you ever wondered how cotton and other fabrics turn into the clothes we love?

Textile mills play a big part in this transformation.

The process begins with turning fibers into yarn. Then, these yarns are woven into fabric. After that, the fabric is dyed to give it color.

This whole process is a mix of old and new ways of doing things. Thanks to modern mills, making fabric is much easier than before.

Join us in taking a closer look at the way textile mills operate and learn more about textile production processes.

The Historical Evolution of Textile Mills

Textile mills are great example of how human creativity and technology have advanced over time. Since early mills and their basic machines, new developments have shaped today’s textile industry, across centuries and continents.

Early Mills: The Foundation of Modern Industry

The story of textile making starts around 6000 B.C. in Southern Turkey, where people first used wool for textiles. Early mills in places like India, with the invention of the Great Wheel in 500 B.C., changed how we made cotton yarn. Then in 1589, an English invention – the first hosiery knitting machine – showed major progress in technology for making textiles. These mills were key to creating jobs and building local economies.

Textile Mills in the Industrial Revolution

The industrial revolution was a big leap for textile mills because of new machines and methods. Eli Whitney’s Cotton Gin in 1793 made producing cotton fabric much easier. Slater Mill in America, started from 1790-92, was the first modern water-powered cotton mill for spinning, leading the way. The 1810 invention of the power loom by Gilmore and Wilkinson was another big step forward. This was also the time when railroads began, helping in making and shipping textiles faster to people all over the nation.

The Impact of the Textile Mills in the 1800s on Textile Production

The 1800s were a time of big change for textile making, with more machines and factory systems. This marked a shift from farming to industry in many places. Lowell, Massachusetts, from 1822-46, was a main center for this change, showing a smart way of running a textile city. By 1870, the U.S. had many woolen and cotton mills, showing how fast and organized textile making had become. This was a time when the American industrial revolution really transformed the U.S., changing how people worked and lived.

These times of change, from the early mills through the industrialization and then the 1800s, are crucial for today’s textile industry. Each phase brought new technology that made producing textiles better, faster, and able to reach more people worldwide.

Fiber Selection: Natural vs. Synthetic

The trip from fiber to fabric is fascinating. It all begins with picking the right fibers. You can choose from natural options like cotton and silk, or go for synthetic fibers such as rayon and nylon. Each type carries its own special qualities and benefits. Knowing this step well is key to understanding the whole process.

Choosing the fibers is a big deal in making textiles. Natural ones include cotton, wool and silk. People have been using these for clothes for thousands of years. They come from plants and animals and offer plenty of choices, such as cotton and wool.

On the other hand, synthetic fibers come from materials like polyester, nylon, and acrylic. These are made by turning polymers into long fibers and then into yarn for fabric. Having these options helps makers meet everyone’s wants and needs.

Spinning: Creating Yarn from Fibers

Spinning machines turn loose fibers into yarn, which is essential. First, cotton plants are grown and the seeds are removed. Then, the fibers are cleaned, carded, and spun into yarn. This yarn is the beginning of every fabric, starting the weaving or knitting process.

Weaving and Knitting: Crafting the Fabric

After making yarn, it’s time to weave or knit. Through these steps, different fabrics take shape. Weaving process makes textiles by crisscrossing yarns, while knitting creates soft, stretchy materials. Many fabrics, including cotton, rayon, denim, and satin, are made this way. They provide warmth, keep away the cold, and protect from rain. The world makes a huge amount of textiles in textile mills worldwide. This long journey respects old ways and includes new ideas, shaping the future of textiles.

Technological Innovations in Textile Mills

Technical breakthroughs have greatly changed textile mills’ abilities. Now, machines play a key role in making textiles better and faster. This has led to more precise work, increased efficiency, and a wider range of fabrics being produced.

The Role of Machinery in Modern Mills

In today’s textile manufacturing landscape, advanced machines form the backbone of production. Over the past decades, automation has transformed the textile machinery, significantly enhancing efficiency despite a reduction in manual labor.

Technologies such as laser printing have revolutionized textile design by facilitating faster and more precise pattern transfers onto fabrics. Similarly, computerized knitting machines have ushered in a new era of mass production for knitted fabrics, boosting both output capabilities and speed in modern mills.

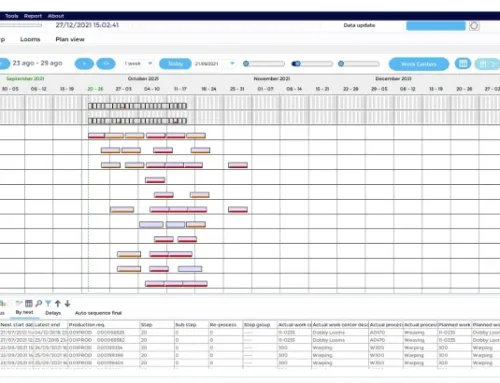

Why ERP for Textile Industry has a crucial role?

To effectively manage these complex operations and optimize production processes, textile manufacturers increasingly rely on integrated textile ERP.

These systems provide comprehensive oversight and control, enabling seamless coordination between design, production, inventory management, and distribution. By leveraging ERP technology, textile companies not only streamline their operations but also enhance their ability to adapt quickly to market demands and maintain competitiveness in a rapidly evolving industry.

In tandem with today’s AI advancements, textile manufacturers are leveraging integrated textile ERP systems to effectively manage complex operations and optimize production processes. These AI-enhanced systems offer huge advantage taking textile business on a whole different level.

Prototyping and Smart Textiles

Prototyping in textiles shows us how innovation can lead to new frontiers. It lets us push the boundaries of what we can do with fabrics. With the help of digital twin technology, prototyping has become more efficient. This helps in marketing and making the industry more sustainable.

Smart textiles are a huge step forward. They use nanotechnology to create fabrics that can feel environmental changes. For example, there are nanotextiles that can resist fire and clean themselves. This innovation not only makes textiles better but also helps the environment by using less energy. The quest for high-performance fabrics using natural and engineered materials is still ongoing. It continues to drive the textile sector forward.

The Dyeing and Finishing Process

The process of dyeing and finishing makes textiles vibrant and appealing. It combines old techniques with new ones. Not only does it introduce color and texture, but it also makes fabrics better using eco-friendly methods.

Traditional Dyeing Techniques

The use of natural dyes has a long history in textiles. English and Scottish experts were especially known for their work, making British cloth highly regarded. These old ways depended on people and nature, making results not always consistent. However, they are valued for their cultural significance and unique looks.

Modern Dyeing Methods and Sustainability

Today, synthetic dyes have made the dyeing industry more diverse and reliable. Piece dyeing keeps white fabrics in stock to prevent unnecessary dyeing. The global market for textile dyeing keeps growing, showing that these methods are crucial. Different dyes suit different materials and needs.

Now, the industry is moving towards eco-friendly dyeing for less harm to the environment. Techniques like solvent dyeing save energy and water, and reduce pollution. Using green technology aims to cut down on water, energy, waste, and pollution in the dyeing process.

Finishing: Enhancing Fabric Qualities

Finishing makes the fabric better for buyers. Most unfinished fabrics are rough and unappealing. But after finishing, they are soft and look good enough to buy. Processes like calendaring and mercerization improve fabric quality and appearance.

There are also new ways like centrifuges to take the water out before drying. Proper drying is key to keep the fabric from feeling rough. The right mix of old and new methods brings out the best in fabrics, making them more desirable.

Sustainability and Ethical Practices in the Textile Industry

The textile industry is changing for a greener, more ethical future. It’s using materials like organic cotton, which are better for the planet. This change is also about using less water, fewer chemicals, and making less waste every year. By making these changes, the industry helps make the world a better place.

Sustainable Manufacturing Processes

Sustainable manufacturing is all about saving energy, making less waste, and recycling, this and much more is obtained by a good clothing ERP software. Doing these things helps keep the earth’s balance. When everyone in the industry works together and follows green rules, it makes a big difference. These efforts show the industry’s promise to protect the planet for the future.