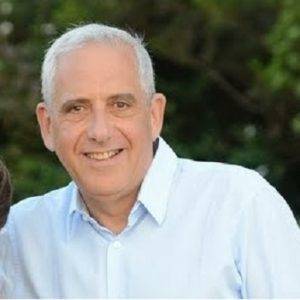

Dieser Artikel basiert auf einer Rede, die unser CEO Ronnie Hagin vor dem Indian Textile Magazine über die Folgen des COVID-Notfalls für die Zukunft der Textilindustrie gehalten hat.

Datatex hat viele Niederlassungen in der ganzen Welt, so dass wir die COVID-Krise von einem globalen Standpunkt aus betrachten konnten.

Sie hatte enorme Auswirkungen auf unser Geschäft, aber es ist wichtig zu betonen, dass wir nicht eine einzige Person entlassen haben. Vor der Pandemie haben wir eine Einstellungskampagne durchgeführt, die wir nun verlangsamt haben. Auf diese Weise konnten wir alle unsere Mitarbeiter behalten, die vollen Zugang zu ihren Büros hatten und von zu Hause aus arbeiten konnten, was man „intelligentes Arbeiten“ nennt. Unsere Lösung NOW ist vollständig webbasiert, so dass wir alle unsere Aktivitäten fast ohne Unterbrechungen fortsetzen konnten.

In dieser Zeit der Ungewissheit und der weit verbreiteten Panik wird das Vermächtnis von COVID – 19 eng mit unserem täglichen Leben verbunden sein und mit der Frage, wie sich jedes Unternehmen neu erfinden muss, um mit diesen Veränderungen fertig zu werden.

Insbesondere ist es wichtig, sich auf den NEUEN SUPPLY CHAIN PARADIGM zu konzentrieren, der sich aus den neuen Lebensstilen der Arbeitnehmer und Kunden ergibt. Während dieser erzwungenen Quarantäne haben sie nämlich neue Gewohnheiten und Bedürfnisse entdeckt.

Insbesondere die Anforderung von Hauslieferungen innerhalb kürzester Zeit ist ein wichtiges Element, das Unternehmen berücksichtigen sollten. Daher können Unternehmen ihre Reaktion auf eingegangene Bestellungen durch die Einführung und Anpassung digitaler Technologien zur Abwicklung der gesamten Lieferkette beschleunigen. Eine Lösung ist der Einsatz von Barcode- oder RFID-Technologien zur Datenerfassung und Automatisierung des Lagerverwaltungsprozesses.

Diese Art der Automatisierung ist mit der Notwendigkeit verbunden, alle Produktions- und Lagerdaten für alle Mitarbeiter von jedem Ort aus verfügbar zu machen. Dieses Ziel kann durch die Einführung eines ERP-Systems erreicht werden, das in der Lage ist, alle Daten zu erfassen, die für die Verwaltung der Unternehmenstätigkeit erforderlich sind. Die verwendete Technologie ist Cloud-basiert und ermöglicht es allen Mitarbeitern, von zu Hause aus zu arbeiten.

Datatex ERP Solution NOW ist vollständig webbasiert und hat intelligente Arbeitsabläufe, vor allem für Verwaltungsbüros, erleichtert, so dass die Benutzer ihre Aufgaben von jedem Ort aus über einen Browser mit ihren Zugangsdaten erledigen können.

Diese Art von Managementsystem ermöglicht es, den Überblick über alle laufenden Projekte zu behalten und alle Informationen an einem einzigen Ort zu sammeln, der jederzeit verfügbar ist. Darüber hinaus ermöglicht die Erstellung von Dashboards, die direkt mit dem Verwaltungssystem verknüpft sind, die Überwachung aller Fortschritte eines einzelnen Projekts und das Verständnis seiner Relevanz für die Unternehmenstätigkeit.

Ein grundlegendes Element eines ERP-Systems ist die Fähigkeit, als Dokumentenmanagementsystem zu arbeiten, das es jeder Abteilung ermöglicht, über alle notwendigen Dokumente zu verfügen, sie in Echtzeit zu ändern und so das gesamte System auf dem neuesten Stand zu halten.

Die Einführung eines ERP-Systems kann insbesondere für Hersteller von medizinischer Ausrüstung und PSA von entscheidender Bedeutung sein. Insbesondere sind Module für Qualitätskontrollen erforderlich, um ein den Normen entsprechendes Qualitätsniveau zu gewährleisten. Wichtig ist auch eine digitale Echtzeit-Kontrolle der eingehenden Materialien. Der Einsatz eines ERP-Systems für Produktion, Inventar und Wartung soll die gesamten Produktions- und Lieferkettenaktivitäten beschleunigen.

NOW hat eine einfache Anwendung, die sich an jeden Bedarf anpassen lässt und es vielen Unternehmen ermöglicht, ihre Prozesse schnell umzustellen, um die heutzutage so wichtigen medizinischen Geräte zu produzieren. In diesem Fall stellen sie Gesichtsmasken und andere Arten von PSA her und überwachen sowohl die Produktqualität als auch die Produktionskosten.

IMPRIMA, das erste multinationale Unternehmen, das sich der Entwicklung und Innovation im Bereich des Textildrucks und der Textilveredelung widmet und seine Produktionsanlagen auf die Herstellung von Masken für zivile Zwecke umgestellt hat.

Ein weiteres Unternehmen, das die Software NOW implementiert hat, um sein Geschäft umzustellen, ist Parkdale Mills in den USA, ein weltweit führendes Unternehmen in der Garnherstellung und Fasertechnologie. In der Tat, fügte es zu seinem aktuellen Angebot, auch wiederverwendbare Baumwolle Gesichtsmasken.